Soil Triaxial Test

Overview

The soil triaxial test is one of the most common testing methods for determining the shear strength of soils. Many different factors affect the shear strength of soils, including the amount of air and water in the soil, so the triaxial test was developed to calculate the shear strength of the soil in many different situations. In a standard triaxial test, a confining stress is applied to the entire cylindrical specimen and an axial stress (usually referred to as the deviator stress) is applied to the top of the specimen. The deviator stress is applied using a loading frame, and since this stress is the greatest stress on the specimen, this is the maximum principal stress, denoted σ1. The confining pressure applied to the specimen is used to simulate the horizontal pressure experienced by the soil at the in-situ depth. In a standard triaxial test, this confining pressure causes the intermediate and the minimum principal stresses, denoted σ2 and σ3, to be equal. This is different from a true triaxial test, where σ1, σ2, and σ3 can each be individually controlled.

In addition to determining the shear strength of the soil, the triaxial test is also used to calculate the angle of internal friction and cohesion of the soil, which are two parameters used most often by geotechnical engineers when attempting to calculate the ability of a soil to be used in various applications, such as under a foundation or as backfill for a retaining wall. In addition, the triaxial test is capable of determining the relationship between the stress and the strain on the soil, which is not possible with simpler shear strength tests, such as the Direct Shear Test or the Simple Shear Test.

Standard Triaxial Cell (Courtesy of GCTS)

How is a Triaxial Test Performed?

A normal triaxial testing system includes a device capable of applying a load to the top of the specimen, a chamber capable of applying a confining pressure to the entirety of a specimen, and systems capable of measuring the load, pressure, and deformation of the specimen. The apparatus for a typical triaxial test is shown in the column to the right. A cylindrical specimen is prepared in the triaxial cell, which is then filled with a liquid, usually water, and pressurized. Water is forced through the bottom of the specimen so that water fills all the voids in the sample and no air remains (complete saturation).

When the sample is fully saturated, the confining pressure is set to a certain value, the specimen is allowed to consolidate (if running a consolidated test, as described below), and then the axial load is applied. The loading piston moves at a constant rate, changing the total height of the specimen constantly with an increasing load. The system measures the load acting on the specimen until it is determined that the specimen is decreasing in height with a constant load. This is defined as the failure of the specimen.

What does a Soil Triaxial Specimen Look Like?

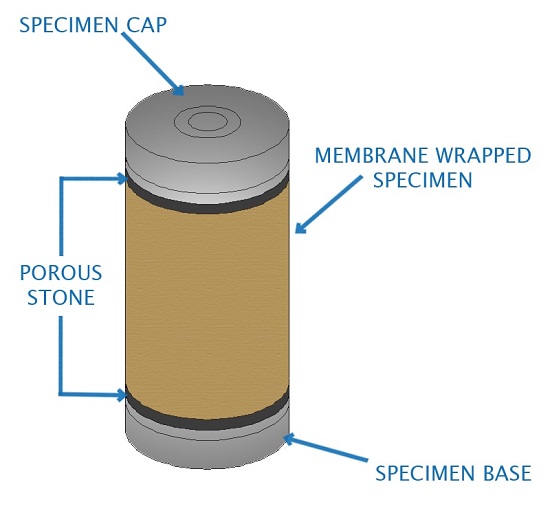

Typical specimens range from 3.3 cm (1.3 in.) to 10.0 cm (4 in.) in diameter, although some testing devices allow for specimens with diameters of up to 1 m. Larger specimens are needed when testing soils with large particle sizes. Specimen height is typically equal to 2 times the diameter, which is done to minimize the friction caused by the caps on the top and bottom of the specimen and to prevent the specimen from buckling during the test. After preparing the specimen, a porous stone is placed on the top and bottom of the specimen, which allows water to move freely into and out of the specimen without allowing any of the soil to move. End caps are then placed on the top and bottom of the specimen to hold everything together. The specimen is then wrapped in a rubber membrane, which provides a seal between the specimen and the confining liquid.

Typical Soil Triaxial Test Specimen

How are Soil Characteristics Determined?

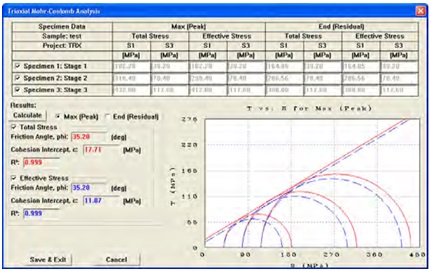

The confining stress is always known during the test, as is the axial (deviator) stress. After performing a test on a soil specimen, a graph is created with principal stresses (total horizontal stress and total vertical stress) on the x-axis and shear stress on the y-axis. The confining stress (the horizontal stress) is plotted with zero shear stress, and the axial stress at failure plus the confining stress (the total vertical stress) is also plotted with zero shear stress. A circle is created using these two points as the diameter. This is known as Mohr’s Circle.

In general, three specimens are tested with different confining pressures and the resulting Mohr’s Circles are all plotted on the same graph. A line is then drawn tangent to all three Mohr’s Circles. This is called the Mohr—Coulomb Failure Envelope. The slope of this line is equal to the angle of internal friction for the soil and the y-intercept of this line is equal to the cohesion of the soil.

Mohr-Coloumb Failure Envelope Output (Courtesy of GCTS)

What are some Different Soil Triaxial Testing Methods?

There are three different tests classified as triaxial compression tests: the Unconsolidated-Undrained Test (UU Test), the Consolidated-Undrained Test (CU Test), and the Consolidated-Drained Test (CD Test).

What is the Unconsolidated-Undrained Test?

In the Unconsolidated-Undrained Test, water is not squeezed out of the soil (not consolidated) before the axial load is applied. This test simulates the conditions of a soil that is loaded very quickly, such as a rapidly constructed building. While the axial load is applied to the specimen during testing, all drainage valves are closed, preventing water from exiting the specimen. The Unconsolidated-Undrained Test is typically used when testing the short-term strength of cohesive soils, such as clays, but cannot be used to test non-cohesive soils, such as sand.

What is the Consolidated-Undrained Test?

In the Consolidated-Undrained Test, the soil is completely saturated as described previously. After saturation, the confining pressure is slowly and incrementally increased to a chosen consolidation pressure, which is typically determined by the field conditions that are being tested. This pressure is increased slowly in order to allow water to be forced out of the specimen without increasing the pore pressure of the water. The consolidation stage is complete when the specimen is no longer changing volume (no more water is draining out) under the maximum consolidation pressure. After consolidation is complete, the drainage valves are closed and the axial load is applied as described above. The Consolidated-Undrained Test is typically used when testing the long and short-term strength of cohesive soils.

What is the Consolidated-Drained Test?

In the Consolidated-Drained test, the soil is allowed to consolidate before testing, using the same procedure as described above. After consolidation, however, the drainage valves remain open while the axial load is applied, allowing water to drain out of the specimen during loading. The rate at which the load is applied is usually slow, which allows water to slowly drain out of the specimen without increasing the pore water pressure. For this test, the change in volume of the specimen is determined by measuring the amount of water that drains from the specimen during the loading phase. The Consolidated-Drained test is used to simulate long-term loading conditions for cohesive and non-cohesive soils.

What Are Some Applications of Soil Triaxial Tests?

There are a number of variations to these three tests that can be used to determine different characteristics of the soil.

Can the Triaxial Test be used for Different Stress Paths?

Typically, the confining pressure is held constant while the axial load is increased. This means that the axial stress is always greater than the radial stress. However, to account for different stress paths (how soil gets from one state of stress to another), the confining pressure can be changed during the test or the axial load can be reversed (which is called a triaxial extension test). By performing a triaxial extension test, the stress in the horizontal direction can be greater than the total stress in the vertical direction. Studying different stress paths is useful for predicting the effects of an earthquake on the soil, when the soil follows many random stress paths in a short amount of time.

Can the Triaxial Test be used for Unsaturated Soils?

Soil triaxial tests can be performed without fully saturating the specimen, although these tests tend to be more complex than normal triaxial tests. This is because the volume change of the specimen is equal to the sum of both the water and the air leaving the specimen during the loading phase, as opposed to just the (measurable) water leaving the specimen in a normal triaxial test. The air within the specimen creates a suction effect on the soil due to capillary forces, which increases the strength of the soil. In order to account for this suction effect, the matric suction (defined as the pore air pressure minus the pore water pressure) inside the soil must be held constant during the entirety of the test, which can only be done with advanced testing systems and software. Unsaturated triaxial tests are useful for determining the response of soils above the groundwater table, which are generally only partially saturated.

Can the Triaxial Test be used for Soils in Hot or Cold Environments?

The triaxial test can be modified with a temperature controlled triaxial cell. Certain systems can change the temperature of the soil from 15°C down to as low as -30°C. Systems such as these, like the one shown below, are useful for determining the characteristics of the soil in both extremely warm and cold climates and determining the change in these properties as the temperature changes throughout the year. A low temperature soil triaxial test is used frequently for gas hydrate testing.

Frozen Soil Triaxial System (Courtesy of GCTS)

What are the Advantages of a Triaxial Test?

During the triaxial test, all stresses on each side of the specimen are known and can be directly controlled by the operator. This means that the stresses applied to the specimen are always the principal stresses, and there is no rotation of these principal stresses like in a Direct Shear test. Due to the large number of tests that can be performed with a triaxial testing system, the strength of the soil under numerous scenarios can be tested. The reaction of the soil under both short-term and long-term loading conditions can be studied, as well as the reaction of the soil undergoing intense stress path variations. By measuring the deformation on the specimen, the relationship between the applied stress and the change in height of the specimen can be determined, allowing for a calculation of the elastic modulus of the soil. During the triaxial test, the specimen is loaded from the top and bottom of the specimen. This means that failure will occur at the weakest point in the soil, rather than on a horizontal plane, as is the case in a Direct Shear test. Finally, recent advanced software and testing devices allow for a complete turn-key

system, where the operator does not need to be in control of the testing apparatus once the test has begun, resulting in fewer operator errors and a more efficient testing procedure.

What are the Disadvangates of a Triaxial Test?

The triaxial testing system as a whole is typically more complicated and more expensive than a Direct Shear test. A Consolidated-Undrained and a Consolidated-Drained will sometimes take much longer than a Direct Shear test, especially if performing the test on clay, as clays generally take a long time to consolidate.

Keywords: Soil Triaxial — Triaxial Test — Triaxial Testing System — Compression Test — Triaxial Testing Machine — Testing Instruments — Saturation — Consolidated — Unconsolidated — Shear Strength — Mohr’s Circle — Stress-Strain Curve — Cohesion — Angle of Internal Friction

© 2016 Geotechnical Consulting and Testing Systems, LLC. All Rights Reserved.